In life, fast food boxes bring convenience to our life. With the development of the fast food industry, they also bring about rapid progress. Now we can not only eat delicious dishes in fast food restaurants and restaurants, but also take them home in packages. It is really a very convenient choice. Disposable fast food box, referred to as foam box. That is, the white foam lunch box is cheap because it is favored by snack bars, small restaurants or all kinds of restaurants. Everyday life is everywhere. So, how much do you know about its security?

When choosing fast food utensils, we should first see whether the logo is complete, and then look at the product. The surface of the product should be smooth, without stains, impurities, scratches, cracks, decolorization and fading. You can also smell to see if there are any irritating odors and other odors. The most important thing is to see the product logo, the product must be labeled manufacturer's name or trademark, material, use temperature and other instructions, if the product has hot water resistance, does not apply to microwave ovens, can not contact oil quality requirements, should also be labeled.

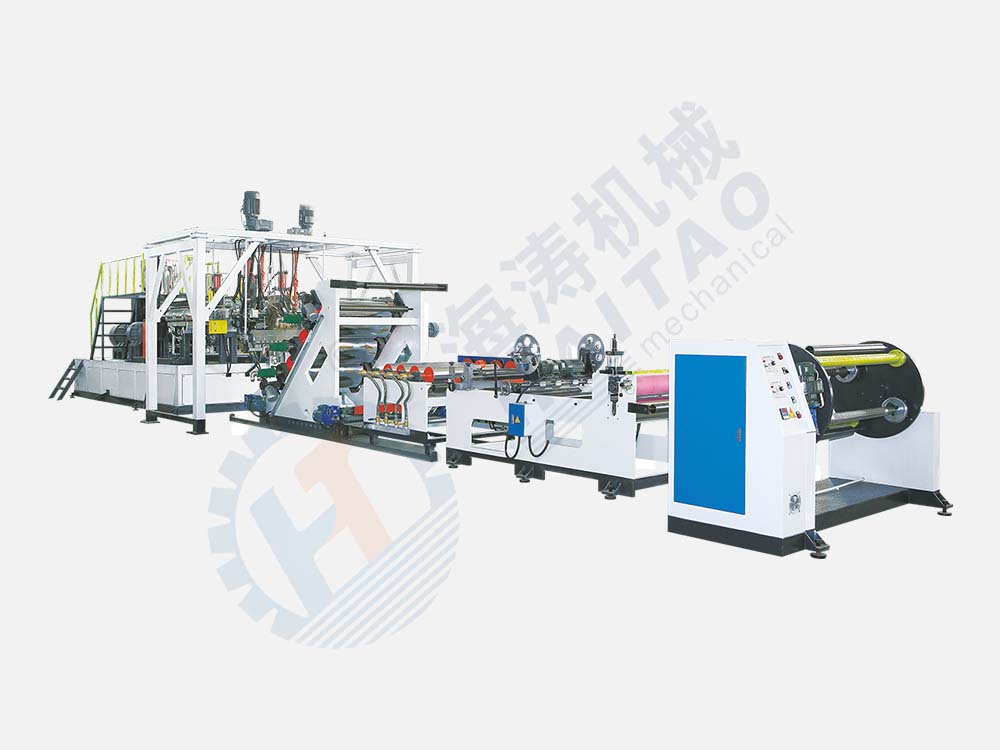

At the same time, the production line of lunch box is the key equipment for crushing materials after they are crushed. It brings great convenience to our life. What should we pay attention to when using the vacuum forming machine for fast food boxes? The increase of the above load and the length of trial run time are determined on the basis of running-in conditions of big and small gears and speed reducer gears. No full load operation shall be allowed until the contact accuracy of the tooth surface fails to meet the design requirements.

PP、PE Green Plastic Lunch Boxes Extrusion Series

The cooling and lubricating system should work normally during commissioning. The temperature of main bearing, transmission bearing and reducer should be normal. After 24-48 hours of trial operation of 2/3 steel balls, all bolts should be checked and tightened again. All records should be carefully recorded in the trial operation. The continuous operation time of air operation is not less than 12-24 hours. Problems found in operation should be solved in time.

The idle test machine can carry out load test operation when it is in normal condition. Load commissioning should be carried out in stages. Feeding should be carried out according to the discharge during load operation to avoid unnecessary wear and damage of steel balls and cylinder liners.