Single screw plastic extruder in the start of heating process is to open several sections of the temperature at the same time to start heating, of course, this method is more commonly used, but this often in the screw temperature reached a certain target, the die temperature of this piece of steel is thicker, larger area), so everyone in this situation. The next is to heat the screw, and then wait until the die temperature slowly rises to the set temperature before starting the operation, which is the most energy-saving approach.

Of course, on the one hand, we need to pay attention to this process, in fact, a simple sequential heating process can help you save a lot of electricity. When heating at the same time in several heating periods, when the temperature of the screw of the plastic extruder reaches the beginning of remember the time, and then wait until the die temperature reaches the set temperature. Note the time, there is a time gap, that is, the time gap between the screw to reach the set temperature and the die to reach the set temperature is how many minutes? Find out at this time, you in this time difference figure so long in advance for the die first heating, until the time difference is reached, then open the screw heating, and so on. It can also save electricity.

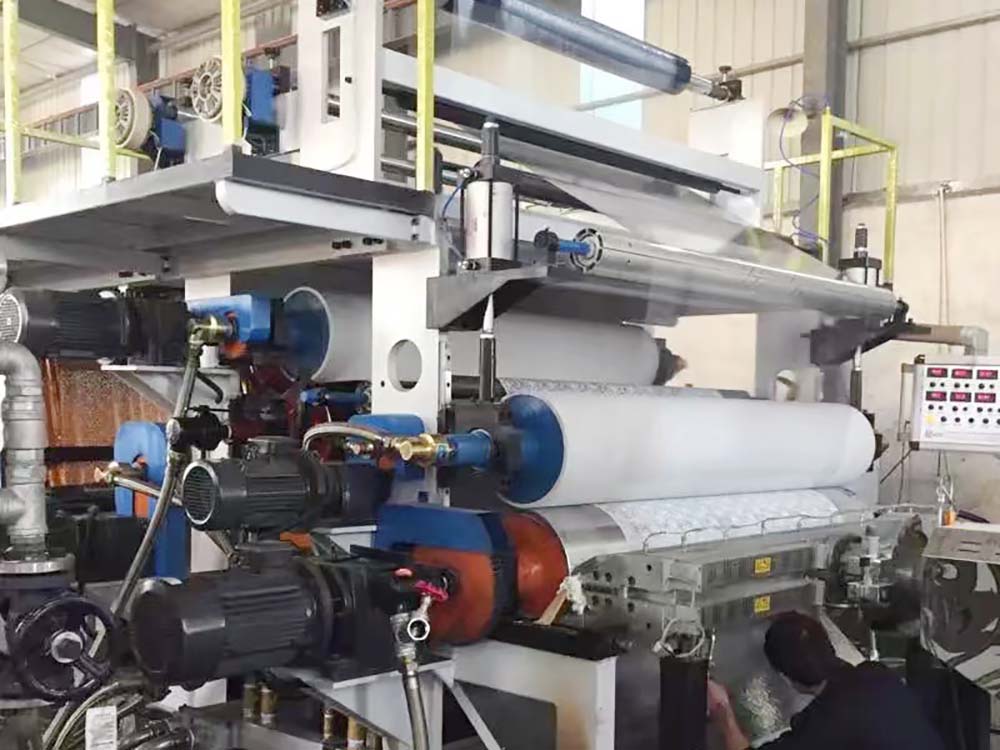

As a common basic equipment, single screw plastic extruder is often used in the plastic processing industry, but because our country is mainly high-power, if not energy-saving, it will consume a lot of resources. It can save electricity by mastering some skills.