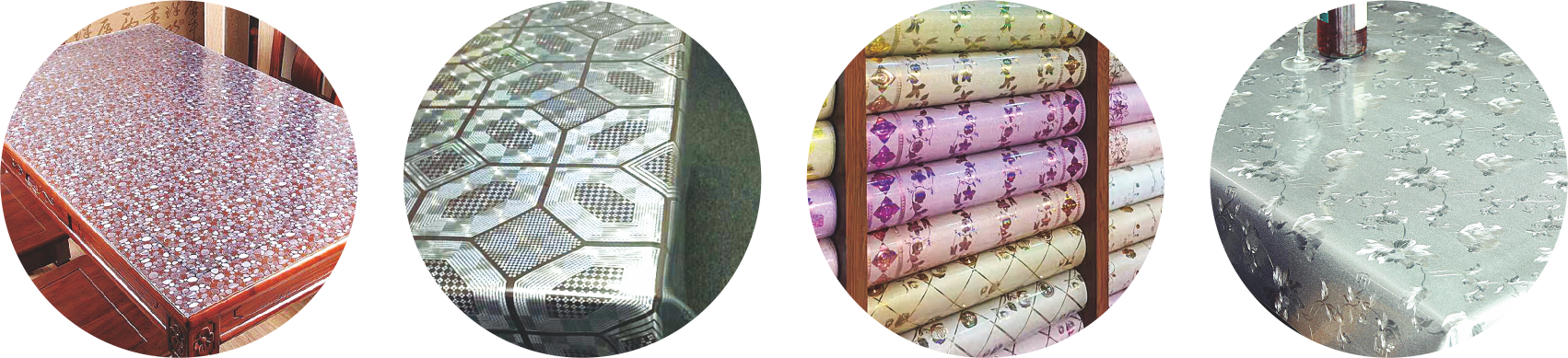

With the continuous improvement of people's living standards, the demand for the decoration effect of housing and public facilities in the process of life, work and urbanization transformation is getting higher and higher, and the resource consumption for decoration is also increasing year by year, which leads to the scarcity of resources. In order to meet the needs of everyone, at present, embossing on PVC sheets is generally used to replace the natural patterns on the surface of the original decorative materials. In order to improve the production efficiency of decorative film and expand its production scale, the use of embossing machine to produce PVC sheets has become the mainstream of development.

In the existing embossing machine, when checking and replacing embossing rolls due to the wear of embossing rolls or the need to replace embossing rolls, the whole device needs to be disassembled, which consumes time and manpower.

The first feeding device transmits the first sheet of PVC (usually PVC printed sheet) to the bonding device, and the second feeding device transmits the second sheet of PVC (usually PVC wear-resistant sheet) to the bonding device. The second feeding device transmits the second sheet of PVC (usually PVC wear-resistant sheet). ) The two kinds of PVC sheets pass through the embossing device and the cooling device in turn after the bonding device is bonded to the bonding device.